×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- BMW Parts

- BMW Accessories

My Garage

My Account

Cart

Genuine BMW 2500 Brake Master Cylinder

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orSeries

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Brake Master Cylinder found

BMW 2500 Brake Master Cylinder

If you are looking for OEM BMW 2500 Brake Master Cylinder, we highly recommend to shop with us. Not only do we offer budget friendly prices, but we also provide fast delivery. In addition, we have a hassle-free return policy on all genuine BMW 2500 Brake Master Cylinder that come backed by the manufacturer's warranty.

BMW 2500 Brake Master Cylinder Parts Questions & Experts Answers

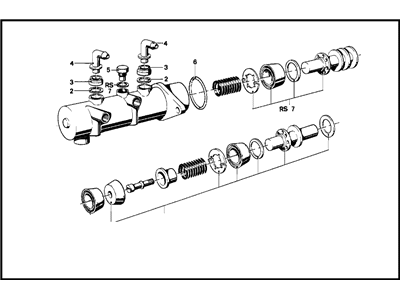

- Q: How do you properly dismantle and reassemble a master cylinder while ensuring cleanliness and correct operation on BMW 2500?A:Plug the fluid outlets in the reservoir and pull the flexible hoses from the sealing plugs in the brake master cylinder. To prevent fluid loss, raise the free ends of the flexible hoses above the fluid level in the reservoir and tie them. Disconnect the brake pipes from the brake master cylinder, noting the connections: 1 front right-hand, 2 front left-hand (second brake circuit), 3 front right-hand, 4 front left-hand, and 5 both rear brakes (first brake circuit). Plug the open ends of the pipes to keep dirt out. Unscrew the mounting nuts and detach the brake master cylinder, collecting the sealing ring between the mounting flange and the brake servo unit. To dismantle, press the secondary piston down slightly to relieve spring pressure, then remove the stop screw and circlip, extracting the secondary piston assembly. Remove the stop washer, seals, and intermediate ring. Dismantle the piston assembly by removing the special screw, spring cap, spring, spring cup, pressure plate, and seals. Use low-pressure compressed air to eject the primary piston, then remove its spring, spring cup, pressure plate, and seals. Wash all parts in approved cleaners, inspect for wear or damage, and renew any faulty components, ensuring to use new rubber seals and a new copper gasket for the stop screw. Maintain cleanliness during reassembly, coating internal components with brake cylinder paste or approved brake fluid. Clamp the brake master cylinder vertically in a vice with the open end down to prevent displacement of internal components. Use tool 6063 if available to ensure seals are correctly entered; if not, carefully enter seals using fingers without turning back the lips. Reassemble in reverse order, ensuring the primary piston assembly is pushed down against spring pressure before inserting the stop screw to retain it in position. Before installing the brake master cylinder assembly, check the sealing ring and renew if necessary to ensure proper operation of the vacuum servo unit. Temporarily install the brake master cylinder assembly with a piece of Plastigage between the piston and the servo pushrod, tighten the nuts to the specified torque, then remove the brake master cylinder to check the Plastigage thickness, which should be 0.5mm (0.02in). Adjust the clearance if necessary by adding a shim of suitable thickness, then install the brake master cylinder assembly in reverse order of removal and bleed the braking system.