×

- Live Chat

- 1-888-580-1680

My Garage

My Account

Cart

Genuine BMW 2500 Fuel Pump

Gas Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orSeries

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Fuel Pump found

BMW 2500 Fuel Pump

If you are looking for OEM BMW 2500 Fuel Pump, we highly recommend to shop with us. Not only do we offer the most budget friendly prices, but we also provide fast delivery. In addition, we have a hassle-free return policy on all genuine BMW 2500 Fuel Pump that come backed by the manufacturer's warranty.

BMW 2500 Fuel Pump Parts Questions & Experts Answers

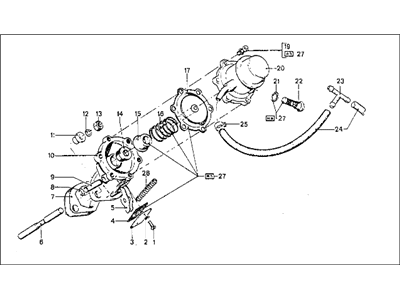

- Q: How should you test and service a fuel pump on BMW 2500?A: Before testing the pump, ensure that the fuel tank vent system is not blocked, as a blockage is indicated by a sound of air being drawn into the tank when the fuel filler cap is removed. If the vent system is clear but fuel is still suspected not to be reaching the carburettors, disconnect the carburetter feed pipe and hold a suitable container under the end of the pipe. Turn the engine over with the starter or switch on the ignition and watch for fuel squirting from the pipe, indicating that the pump is working; if so, check the float needles in the carburettors for possible sticking. Reduced fuel flow can result from a blocked fuel pipe or a clogged filter, so if a clogged fuel line filter is suspected, remove it and check for free fuel flow. An obstructed pipeline may be cleared with compressed air, but do not pass compressed air through the pump or the valves will be damaged. If the pump delivers insufficient fuel, suspect an air leak between the pump and the tank, dirt under the pump valves, or faulty valve seatings; if no fuel is delivered, suspect a sticking valve or a faulty pump diaphragm. Test the action of the pump valves by blowing and sucking at the inlet and outlet points, ensuring that air can be blown in through the pump inlet but not sucked out, and that air can be sucked out of the pump outlet but not blown in. If the valves do not work properly or if the pump is defective, the unit must be overhauled or renewed, noting that no servicing is possible for electrically operated pumps. For a diaphragm pump, remove the air cleaner assembly, unscrew and remove the cap and filter gauze; for an electrically operated pump, disconnect the fuel inlet hose and remove the filter gauze. Wash the filter gauze in clean petrol, using a small brush for stubborn deposits, and renew it if damaged. Reinstall the filter in the reverse order of removal, refitting the air cleaner if it was removed. To remove a diaphragm pump, disconnect the fuel pipes, plug or clamp the ends to prevent fuel loss, unscrew the fixing nuts, and remove the pump from the insulating flange, checking the condition of the pump pushrod and insulating flange. Refit the pump using new gaskets and tighten the mounting nuts alternately and evenly. For an electrically operated pump, disconnect the plug by pulling on the plug body, disconnect the fuel inlet pipe, and remove the filter gauze. Disconnect the fuel delivery hose from the expansion vessel, plug or clamp the ends of the hoses, and remove the fuel pump with the expansion vessel. Renew the fuel pump completely if faulty, as no repairs are possible. Refit the pump in reverse order, ensuring the plug is correctly connected. For diaphragm pump overhaul, mark the upper and lower parts for reassembly, remove screws to separate the parts, check the inlet and outlet valves, wash the pump upper part in petrol, and clean the filter element. Dismantle the lower components, discarding the diaphragm and fitting a new one, checking all other components for wear or damage. Clean the pump lower body with petrol, reassemble in reverse order, ensuring the rocker arm engages the diaphragm pushrod correctly, and position the diaphragm properly before tightening the retaining screws.