×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- BMW Parts

- BMW Accessories

My Garage

My Account

Cart

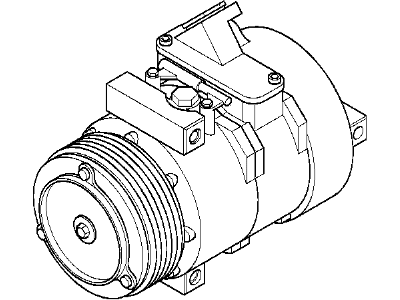

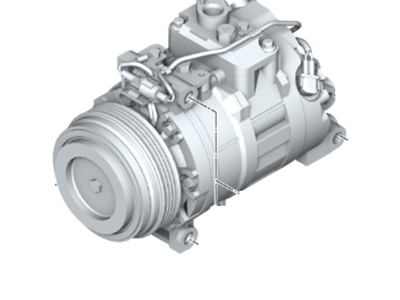

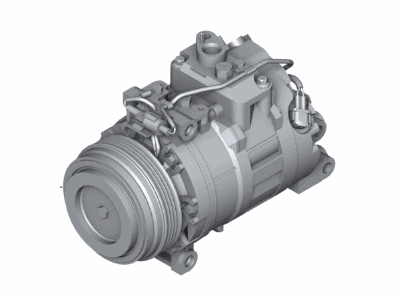

Genuine BMW X5 A/C Compressor

Air Conditioning Compressor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orSeries

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

35 A/C Compressors found

BMW X5 ELECTRIC A/C COMPRESSOR

Part Number: 64529496106$1658.02 MSRP: $2309.35You Save: $651.33 (29%)Ships in 1-3 Business DaysBMW X5 Air Conditioning Compressor With Magnetic Coupling

Part Number: 64529399060$1059.18 MSRP: $1475.26You Save: $416.08 (29%)Ships in 1-3 Business DaysBMW X5 Air Conditioning Compressor With Magnetic Coupling

Part Number: 64529399059$1059.18 MSRP: $1475.26You Save: $416.08 (29%)Ships in 1-3 Business DaysBMW X5 Air Conditioning Compressor With Magnetic Coupling

Part Number: 64529217868$1059.18 MSRP: $1475.26You Save: $416.08 (29%)Ships in 1-3 Business DaysBMW X5 Air Conditioning Compressor

Part Number: 64526909628$1220.43 MSRP: $1699.85You Save: $479.42 (29%)Ships in 1-3 Business DaysBMW X5 RP A/C COMPRESSOR WITH MAGNE

Part Number: 64529890655$1337.40 MSRP: $1862.77You Save: $525.37 (29%)Ships in 1-3 Business DaysBMW X5 Air Conditioning Compressor With Magnetic Coupling

Part Number: 64509154072$1059.18 MSRP: $1475.26You Save: $416.08 (29%)Ships in 1-3 Business DaysBMW X5 Air Conditioning Compressor Without Magnetic Coupling

Part Number: 64509192317$969.12 MSRP: $1349.82You Save: $380.70 (29%)Ships in 1-3 Business DaysBMW X5 Exchange Air Conditioning Compressor

Part Number: 64526921651$1220.43 MSRP: $1699.85You Save: $479.42 (29%)Ships in 1-3 Business DaysBMW X5 A/C COMPRESSOR W/O MAGNETIC

Part Number: 64529890656$1228.16 MSRP: $1710.63You Save: $482.47 (29%)Ships in 1-3 Business DaysBMW X5 Air Conditioning Compressor

Part Number: 64526822848$1278.92 MSRP: $1781.32You Save: $502.40 (29%)Ships in 1-3 Business DaysBMW X5 Air Conditioning Compressor

Part Number: 64509121758$1059.18 MSRP: $1475.26You Save: $416.08 (29%)Ships in 1-3 Business DaysBMW X5 Air Conditioning Compressor

Part Number: 64529185142$1059.18 MSRP: $1475.26You Save: $416.08 (29%)Ships in 1-3 Business DaysBMW X5 Air Conditioning Compressor

Part Number: 64529185143$1059.18 MSRP: $1475.26You Save: $416.08 (29%)Ships in 1-3 Business DaysBMW X5 AIR COND.COMPRESSOR W/ MAGNE

Part Number: 64525A58A52$1278.92 MSRP: $1781.32You Save: $502.40 (29%)Ships in 1-2 Business DaysBMW X5 Air Conditioning Compressor With Magnetic Coupling

Part Number: 64529185145$1059.18 MSRP: $1475.26You Save: $416.08 (29%)Ships in 1-3 Business DaysBMW X5 Electric Air Conditioning Compressor

Part Number: 64526998210$1658.02 MSRP: $2309.35You Save: $651.33 (29%)Ships in 1-3 Business DaysBMW X5 RP A/C COMPRESSOR W/O MAGNET

Part Number: 64526995919$1228.16 MSRP: $1710.63You Save: $482.47 (29%)Ships in 1-3 Business DaysBMW X5 Air Conditioning Compressor Without Magnetic Coupling

Part Number: 64509121760$969.12 MSRP: $1349.82You Save: $380.70 (29%)Ships in 1-3 Business DaysBMW X5 Air Conditioning Compressor Without Magnetic Coupling

Part Number: 64529185144$969.12 MSRP: $1349.82You Save: $380.70 (29%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 35 Results

BMW X5 A/C Compressor

If you are looking for OEM BMW X5 A/C Compressor, we highly recommend to shop with us. Not only do we offer budget friendly prices, but we also provide fast delivery. In addition, we have a hassle-free return policy on all genuine BMW X5 A/C Compressor that come backed by the manufacturer's warranty.

BMW X5 A/C Compressor Parts Questions & Experts Answers

- Q: How do you properly remove and install an A/C compressor following the manufacturer's instructions on BMW X5?A:Following manufacturer's instructions, connect an approved refrigerant recovery, recycling, or recharging unit to the A/C system and discharge system. Raise the car and support it safely, then remove the splash shield from under the engine. With the engine fully cooled off, drain the cooling system. Mark the A/C drive belt with the direction of rotation and remove it. Remove the air filter housing. Working above the right front of the engine compartment, squeeze the plastic junction at the secondary air valve to separate the air intake hose and tie it to the side to gain access to the A/C compressor. Remove Allen mounting bolts and pull off refrigerant lines, plugging them and the ports immediately to prevent contamination. Detach the coolant hose from the right side of the thermostat housing. Working underneath the vehicle at the radiator outlet hose, detach the radiator outlet coolant temperature sensor, then detach the coolant hose from the radiator and remove it, along with the mounting plate underneath the radiator. Underneath the vehicle, detach the compressor electrical connector, cover the frame rail underneath the compressor, remove the compressor mounting bolts, and lift out the compressor with refrigerant lines attached. Separate the lines from the compressor on a workbench, ensuring to replace sealing O-rings when reattaching refrigerant lines. Installation is the reverse of removal, with sealing O-rings replaced when reconnecting refrigerant lines. If installing a new compressor or if the compressor is off the vehicle for more than 24 hours, replace the receiver-drier unit. Install and tension the NC drive belt, noting the previously made direction mark. Fill and bleed the cooling system, then recharge the NC system following the equipment manufacturer's instructions. When starting a new compressor for the first time, switch on the NC system, set air vents to OPEN, start the engine and allow it to idle, set blower output to 75% of maximum, and run the NC for at least 2 minutes at idle speed (under 1500 rpm), as the new compressor may be damaged if run at higher than idle speed at start-up.

Related BMW X5 Parts

Browse by Year

2024 A/C Compressor 2023 A/C Compressor 2022 A/C Compressor 2021 A/C Compressor 2020 A/C Compressor 2019 A/C Compressor 2018 A/C Compressor 2017 A/C Compressor 2016 A/C Compressor 2015 A/C Compressor 2014 A/C Compressor 2013 A/C Compressor 2012 A/C Compressor 2011 A/C Compressor 2010 A/C Compressor 2009 A/C Compressor 2008 A/C Compressor 2007 A/C Compressor 2006 A/C Compressor 2005 A/C Compressor 2004 A/C Compressor 2003 A/C Compressor 2002 A/C Compressor 2001 A/C Compressor 2000 A/C Compressor