×

- Live Chat

- 1-888-580-1680

My Garage

My Account

Cart

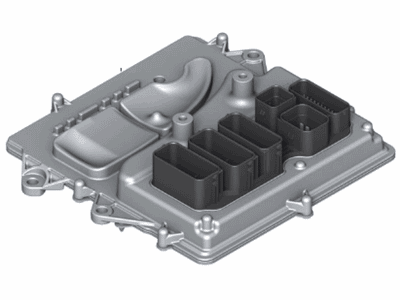

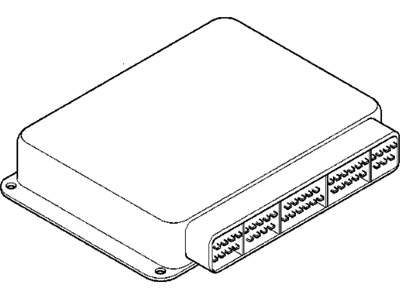

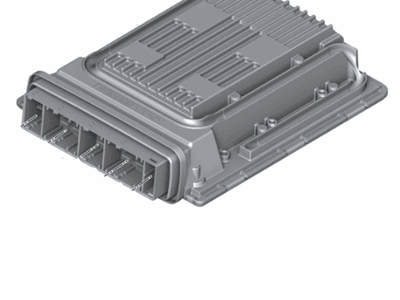

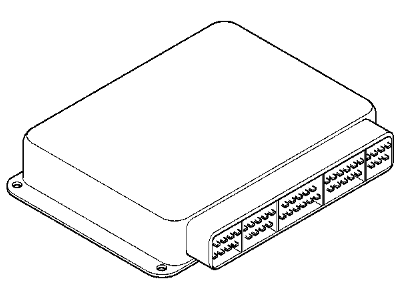

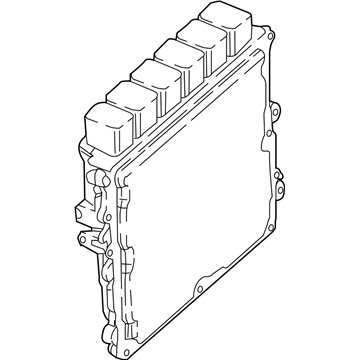

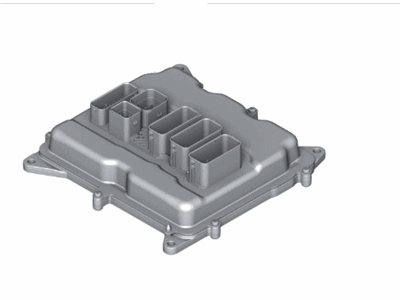

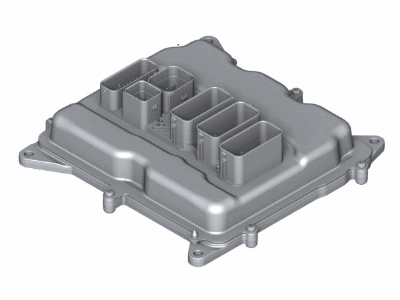

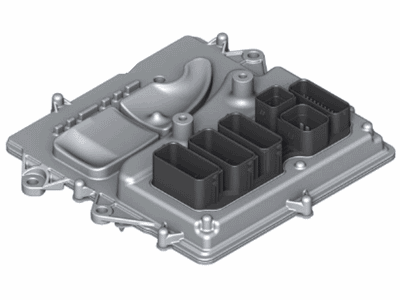

Genuine BMW X5 Engine Control Module

Engine Control Computer- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orSeries

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

124 Engine Control Modules found

BMW X5 Engine Control Module

Part Number: 12148618483$1740.82 MSRP: $2210.74You Save: $469.92 (22%)Ships in 1-3 Business DaysBMW X5 Engine Control Module

Part Number: 12148674949$1740.82 MSRP: $2210.74You Save: $469.92 (22%)Ships in 1-3 Business DaysBMW X5 Engine Control Module

Part Number: 12142461573$1740.82 MSRP: $2210.74You Save: $469.92 (22%)Ships in 1-3 Business DaysBMW X5 DME Engine Control Module

Part Number: 12147555400$1740.82 MSRP: $2210.74You Save: $469.92 (22%)Ships in 1-3 Business DaysBMW X5 Engine Control Module

Part Number: 12147558440$1799.17 MSRP: $2284.84You Save: $485.67 (22%)Ships in 1-3 Business DaysBMW X5 Engine Control Module

Part Number: 12147649411$1740.82 MSRP: $2210.74You Save: $469.92 (22%)Ships in 1-3 Business DaysBMW X5 Engine Control Module

Part Number: 12147558442$1799.17 MSRP: $2284.84You Save: $485.67 (22%)Ships in 1-3 Business DaysBMW X5 BASIC COTROL UNIT DME

Part Number: 12145A059D8$1740.82 MSRP: $2210.74You Save: $469.92 (22%)Ships in 1-3 Business DaysBMW X5 Dme Engine Control Module

Part Number: 12147540738$1740.82 MSRP: $2210.74You Save: $469.92 (22%)Ships in 1-3 Business DaysBMW X5 Engine Control Module

Part Number: 13618572479$2379.98 MSRP: $2936.07You Save: $556.09 (19%)Ships in 1-3 Business DaysBMW X5 Dme Engine Control Module

Part Number: 12148689181$1740.82 MSRP: $2210.74You Save: $469.92 (22%)Ships in 1-3 Business DaysBMW X5 Dme Engine Control Module

Part Number: 12148617572$1740.82 MSRP: $2210.74You Save: $469.92 (22%)Ships in 1-3 Business DaysBMW X5 BASIC COTROL UNIT DME

Part Number: 12149468879$2088.99 MSRP: $2652.88You Save: $563.89 (22%)Ships in 1-3 Business DaysBMW X5 Engine Control Module

Part Number: 12147522802$1271.91 MSRP: $1639.36You Save: $367.45 (23%)Ships in 1-3 Business DaysBMW X5 Dme Engine Control Module

Part Number: 12147532675$1271.91 MSRP: $1639.36You Save: $367.45 (23%)Ships in 1-3 Business DaysBMW X5 Engine Control Module

Part Number: 12147533707$1271.91 MSRP: $1639.36You Save: $367.45 (23%)Ships in 1-3 Business DaysBMW X5 Engine Control Module

Part Number: 12147551616$1271.91 MSRP: $1639.36You Save: $367.45 (23%)Ships in 1-3 Business DaysBMW X5 Engine Control Module

Part Number: 12142461572$1511.82 MSRP: $1948.57You Save: $436.75 (23%)Ships in 1-3 Business DaysBMW X5 Engine Control Module

Part Number: 12147542250$1511.82 MSRP: $1948.57You Save: $436.75 (23%)Ships in 1-3 Business DaysBMW X5 Dme Engine Control Module

Part Number: 12147542300$1511.82 MSRP: $1948.57You Save: $436.75 (23%)Ships in 1-3 Business Days

| Page 1 of 7 |Next >

1-20 of 124 Results

BMW X5 Engine Control Module

If you are looking for OEM BMW X5 Engine Control Module, we highly recommend to shop with us. Not only do we offer the most budget friendly prices, but we also provide fast delivery. In addition, we have a hassle-free return policy on all genuine BMW X5 Engine Control Module that come backed by the manufacturer's warranty.

BMW X5 Engine Control Module Parts Questions & Experts Answers

- Q: What is the function and features of the engine control module on BMW X5?A: The module that handles the operation of the engine is called the engine control module (ECM), located in the electronics box in the right rear of the engine compartment, the part of the ECM that is specific to this model can be updated with a flash programmer this module has 5 electrical wiring harness connectors containing a total of 134 pins. The EEPROM is embedded in the ECM and is different for each make of car; it can be flashed up to 13 times. The ECM meters pressurised fuel by controlling duration of the Fuel Injector opening and the fuel pump pressures are adjusted, such that pulse/width of the injector is the only factor need for fuel . Fuel injectors deliver fuel at an angle in a dual cone pattern The size, shape, and opening duration of injectors are controlled by ECM depending with the engine's conditions so as to have cylinder selective fuel trim. The air filtered through a pleated paper element is located in the air filter housing and the intake Air Mass is determined by a Mass Air Flow Sensor which employs heated thin film to weigh the incoming air mass. Engine idle speed is regulated by idle speed control valve, the which bypasses air in different quantities around the closed throttle valve, and the ECM governs the idle speed depending on the Engine warm-up and A/C. If the Idle Control Valve is faulty then the ECM will adjust the air flow so as to sustain the idle rate. Electronic throttle control is used for the throttle control hence there is no throttle cable used. An indication of ignition knock is detected and the engine management computes the correct ignition timing and here the knock sensors work like microphone that translates mechanical vibrations into an electrical signal.

Related BMW X5 Parts

Browse by Year

2024 Engine Control Module 2023 Engine Control Module 2022 Engine Control Module 2021 Engine Control Module 2020 Engine Control Module 2019 Engine Control Module 2018 Engine Control Module 2017 Engine Control Module 2016 Engine Control Module 2015 Engine Control Module 2014 Engine Control Module 2013 Engine Control Module 2012 Engine Control Module 2011 Engine Control Module 2010 Engine Control Module 2009 Engine Control Module 2008 Engine Control Module 2007 Engine Control Module 2006 Engine Control Module 2005 Engine Control Module 2004 Engine Control Module 2003 Engine Control Module 2002 Engine Control Module 2001 Engine Control Module 2000 Engine Control Module