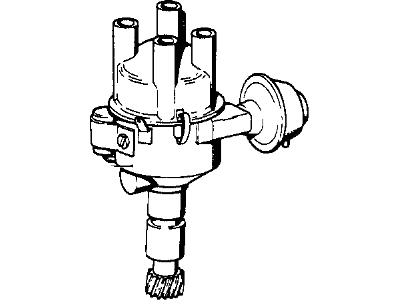

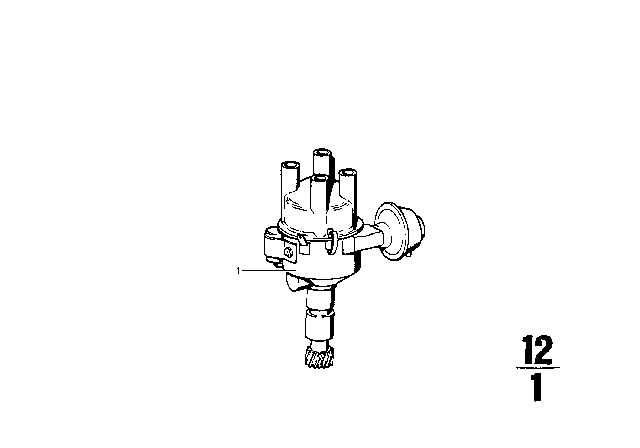

To ensure reliability, purchase BMW part # 12111271717 Distributor. It is sometimes referred to as BMW Distributor. Genuine parts are first-rate in terms of quality and functionality. Manufactured directly by BMW, they undergo rigorous testing and are made from dependable materials to ensure long-lasting durability and dependability. This part fits 1968-1976 BMW 2002.

BMWPartsDeal.com is a leading supplier of genuine BMW parts and accessories such as BMW 12-11-1-271-717 Distributor. In need of brand new OEM BMW parts? Feel free to browse through our extensive catalog of genuine BMW parts, all priced at the most competitive rates in the market. Furthermore, every part comes with a manufacturer's warranty and a hassle-free return policy for your convenience.