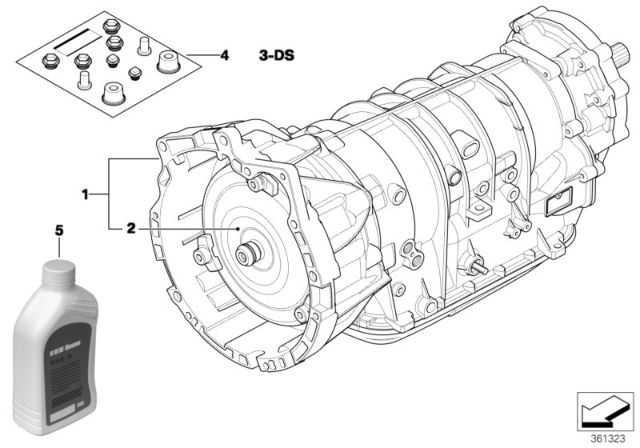

Automatic transition removal varies slightly depending on the installed transmission, with the following procedure specific to the GM GA6L45R 6-speed transmission, which can also serve as a guide for the GM A5S390R 5-speed transmission. Begin by disconnecting the negative cable from the battery, ensuring to read the battery connection cautions beforehand. Remove the electric radiator fan and support the weight of the engine from above using an engine support brace, screwing a tow hook into the cylinder head for the N52 engine. Raise and safely support the vehicle, then remove splash shields and supporting brackets under the engine and transmission. Take off the front aluminum reinforcement plate from the front suspension subframe, discarding the bolts, and remove the exhaust system along with the exhaust heat shields and support bracket by unfastening and unclipping lines. For the N52 engine, separate the oxygen sensor electrical connectors and remove the connector retaining plate. Remove the bellhousing fastener next to the electrical connector brackets, counter-holding the clamping sleeve to loosen the nut, and then remove the retaining bracket bolts, setting the cable aside. Detach the transmission fluid cooler hydraulic lines by removing the hold-down bolt and the nut and bracket holding the lines to the engine, ensuring to catch any dripping fluid and replace O-rings with new ones. Support the transmission from below with a suitable jack, remove the fasteners for the transmission crossmember, and proceed to remove the front driveshaft. For the rear driveshaft, remove the center bearing support fasteners, support the center of the driveshaft, detach the flex-disc from the transfer case, and lower the center sufficiently to disengage the flex-disc, tying the driveshaft to the side. Disconnect harness connectors from the servomotor on the transfer case, then crank the engine by hand until the first fastener is visible through the access hole in the transmission bell housing, removing it and continuing to rotate the engine to remove the remaining torque converter fasteners. Insert the torque converter locking tool to secure the torque converter and release the mechatronics electrical connector bayonet lock, carefully pulling the connector off the pins. Insert a protective cover in place of the mechatronics connector, taking care not to touch or damage the electrical pins. Remove the remaining fasteners from the transmission bell housing and pull the transmission back and down, lowering the jack slowly while ensuring no lines, hoses, or wires become snagged. Be cautious of tilting the engine during removal to avoid damage and use a special tool to hold the torque converter in place. Blow out oil cooler lines with low-pressure compressed air and flush the cooler with clean ATF twice, wearing safety glasses and not reusing the ATF. Inspect the engine drive plate and flywheel for cracks or elongated holes, replacing them if necessary, and if the torque converter seal is leaky or disturbed, replace the torque converter seal. For installation, rotate the flywheel until the bore is accessible, check that dowel sleeves are in good shape, and ensure the torque converter is seated correctly. Join the transmission to the engine, replacing all aluminum fasteners and following the tightening sequence, tightening the bell housing bolts to initial torque and using new aluminum fasteners for N52 engines. The remainder of the installation is the reverse of removal, tightening fasteners to final torque, installing new sealing washers or O-rings on ATF cooling line fittings, checking the gearshift mechanism, and filling the transmission with clean ATF.

Posted by BMWPartsDeal Specialist