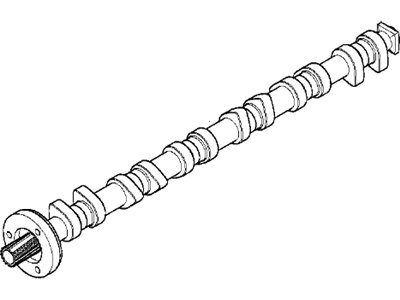

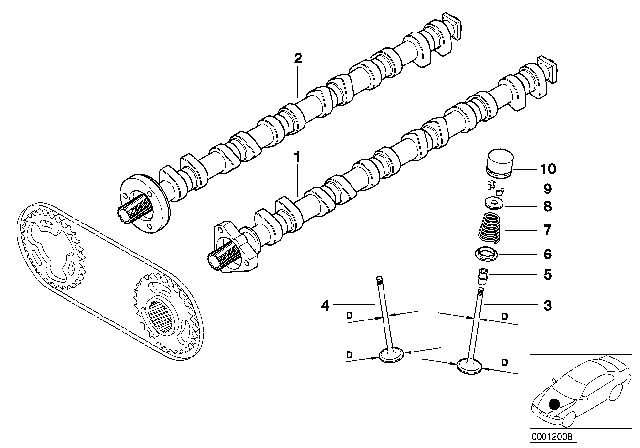

Before installing camshaft carriers, examine hydraulic lifter bore bearing points on the underside of camshaft carriers for signs of wear. Lubricate camshafts, camshaft carriers, bearing caps, hydraulic lifters, and friction washers with assembly lubricant. Center the camshaft carrier with hydraulic lifters on pins at bearing positions 2 and 7, noting marks on camshaft carriers: E for intake side and A for exhaust side. Lift the timing chain and place the exhaust camshaft on the exhaust camshaft carrier, followed by the intake camshaft on the intake camshaft carrier. Place bearing caps on camshafts and install retaining nuts finger tight, ensuring each bearing cap is marked E1 to E7 for intake and A1 to A7 for exhaust. Ensure the crankshaft, rotated approximately 30° opposite the direction of engine rotation from TDC, remains in that position. Fit BMW special tools 113260 and 113270 to the cylinder head and screw long bolts into spark plug threads, aligning tensioning pins on the tool with bearing caps on the intake camshaft. Rotate the eccentric shaft of the special tool to pretension bearing caps and torque bearing cap nuts, then release tension on the eccentric shaft and remove the special tools, repeating the procedure for the exhaust camshaft. A minimum waiting time is required for hydraulic lifters to bleed down before bringing the crankshaft and pistons back to TDC. When camshafts are removed, hydraulic lifters may expand, potentially causing increased valve lift when camshafts are bolted down, resulting in interference. Using a 27 mm open-end wrench, rotate the camshaft into position, grinding off outer edges of the wrench jaws if necessary to prevent damage to the cylinder head. Rotate camshafts until intake and exhaust lobes for cylinder 1 face each other, securing camshafts in TDC position using BMW camshaft TDC tools 113241 and locking down with special tool 113244 bolted to a spark plug bore. Lift the timing chain and hold under tension while using the crankshaft vibration damper bolt to rotate the crankshaft in the direction of rotation (clockwise) until cylinder 1 is at TDC position, ensuring OIT on the front pulley lines up with the boss on the lower timing chain cover. Secure the crankshaft in TDC position with BMW special tool 115180. Slide the impulse wheel on the intake camshaft, aligning the boss with the raised portion on the camshaft, and fit the thrust spacer to the intake camshaft, tightening down with threaded locating studs. Fit the primary sprocket to the primary timing chain and install it on the exhaust camshaft so that the pointer on the sprocket lines up with the cylinder head sealing surface. Insert BMW special tool 114220 into the timing chain tensioner bore and bring the center spindle into contact with the tensioning rail, tightening until slack is removed but not pretensioning the timing chain. Ensure the arrow on the upper primary sprocket still lines up with the upper edge of the cylinder head, repositioning the sprocket if necessary. Insert and tighten down threaded locating studs in the end of the exhaust camshaft, noting the installed position of the studs. Install the secondary chain tensioner on the cylinder head, keeping the tensioner compressed using BMW special tool 113291 or a suitable pin tool. Install the exhaust camshaft splined sleeve, confirming that the gap in sleeve splines aligns with the corresponding gap in camshaft splines. Slide the splined shaft on the exhaust camshaft, ensuring the locating tooth of the shaft fits into the spline gaps of the camshaft and splined sleeve, pushing the splined shaft in further to rotate the splined sleeve until three threaded holes in the primary chain sprocket are centered in the splined sleeve slots. Time intake to exhaust sprockets using BMW special tool 116180, positioning the spline gap on the intake sprocket as shown and placing the secondary chain on the sprockets. Remove the chain and sprockets from the tool and slide the sprockets on the camshafts, aligning the gap in the intake sprocket splines with the corresponding gap in the camshaft splines, ensuring not to alter the position of sprockets with respect to the chain when removing from special tool 116180. Slide the splined shaft onto the intake camshaft until approximately 1 mm of splines are visible, then install the intake camshaft spring plate so that the FRONT mark is visible, followed by installing mounting nuts finger tight. Insert sprocket mounting bolts on the exhaust side camshaft assembly, initially tightening to approximately 5 Nm and then backing off by half a turn. Fit the thrust spacer on the exhaust camshaft and install the spring plate to the exhaust camshaft, ensuring that the F mark is visible. If the F mark is no longer visible, install the spring plate with the convex side facing forward. Install the exhaust camshaft impulse wheel, aligning the pointer with the top edge of the cylinder head, and install mounting nuts finger tight. Pull out the exhaust camshaft splined shaft to stop, press down on the secondary chain tensioner, and remove the tensioner lock-down tool. Preload the primary chain by tightening the adjusting screw on BMW special tool 114220 to the specified torque, and preload the exhaust camshaft spring plate by pressing on the impulse wheel while tightening mounting nuts finger tight. Install BMW special tool 116150 to the front of the cylinder head timing case, installing nuts finger tight and then tightening down uniformly until the special tool is in full contact with the cylinder head. Ensure gasket material is removed from the face of the cylinder head, cleaning the sealing face and keeping it free of oil. Secure camshaft sprockets and impulse wheels by tightening mounting screws on the exhaust camshaft impulse wheel to approximately 5 Nm, followed by tightening mounting nuts on exhaust and intake sprocket assemblies to approximately 5 Nm, and then torquing down mounting screws and nuts to final specifications. Remove the crankshaft locking tool so that the crankshaft is no longer secured in TDC position, and remove camshaft locking tools from the cylinder head. Turn the engine over twice in the direction of rotation until cylinder 1 intake and exhaust camshaft lobes face each other, securing the crankshaft in TDC position with BMW special tool 115180. Place BMW special tool set 113240 over camshafts and measure clearances, noting that due to VANOS unit tolerances and play, the intake side of the special tool may be up to 1 mm above the surface of the cylinder head, which is normal. Otherwise, reset camshaft timing, ensuring that if the exhaust side of the tool is not flush with the cylinder head, camshaft timing is incorrect and requires resetting. Remove BMW special tool 116150 from the front of the cylinder head, reinstall the VANOS unit, remove camshaft and crankshaft locking tools, and reassemble the engine, ensuring to top off and bleed the cooling system.

Posted by BMWPartsDeal Specialist