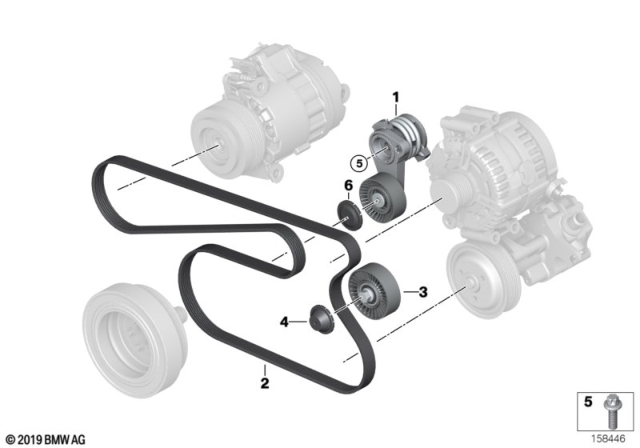

Inspect belt and belt tensioners with the engine off. If the belt displays signs of wear, cracking, glazing, or missing bits, it should be replaced immediately. Belts should be replaced every four years to minimize the risk of failure. Ensure tensioner pulleys are aligned with the belt, and if any misalignment is observed, replace the tensioner assembly.For the M54 engine, there are two belts: the outer belt drives the A/C compressor while the inner belt drives the alternator, coolant pump, and steering pump. Before removing the inner belt, the outer belt must be taken off. If using old belts, mark their rotation direction. Both hydraulic and mechanical belt tensioners are available, but tension release procedures are similar for both. For the A/C compressor belt removal, rotate its tensioner using a hex head or Torx socket, remove the belt, and inspect for damage. When reinstalling, rotate the tensioner and place the belt over pulleys. For the Drive Belt, first remove the A/C compressor belt, then remove the cap from its tensioner. Using a long-handled wrench, release the belt tension, and then remove the belt. When fitting a new belt, ensure it's positioned correctly on the pulleys.For the N52 engine, the Drive Belt transfers power to various components including the alternator and A/C compressor. CAUTION: Only use aluminum fasteners on N52 engines and test them with a magnet to verify their composition, replacing them each time they're loosened. Excessive engine movement due to a faulty left side engine mount can cause belt damage, commonly from contact with the power steering pump pulley. If any damage is observed, replace the affected parts and the left engine mount. To replace the belt, remove the front intake cowl and engine splash shield. Using a T60 Torx socket, release the belt tension. If replacing the belt tensioner, remove the locking tool, pry off the dust cap, and replace the tensioner. Always follow previously marked rotation directions if reusing belts.

Posted by BMWPartsDeal Specialist